JET Tools JWP-15HH User Manual - Page 18

Maintenance

|

View all JET Tools JWP-15HH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

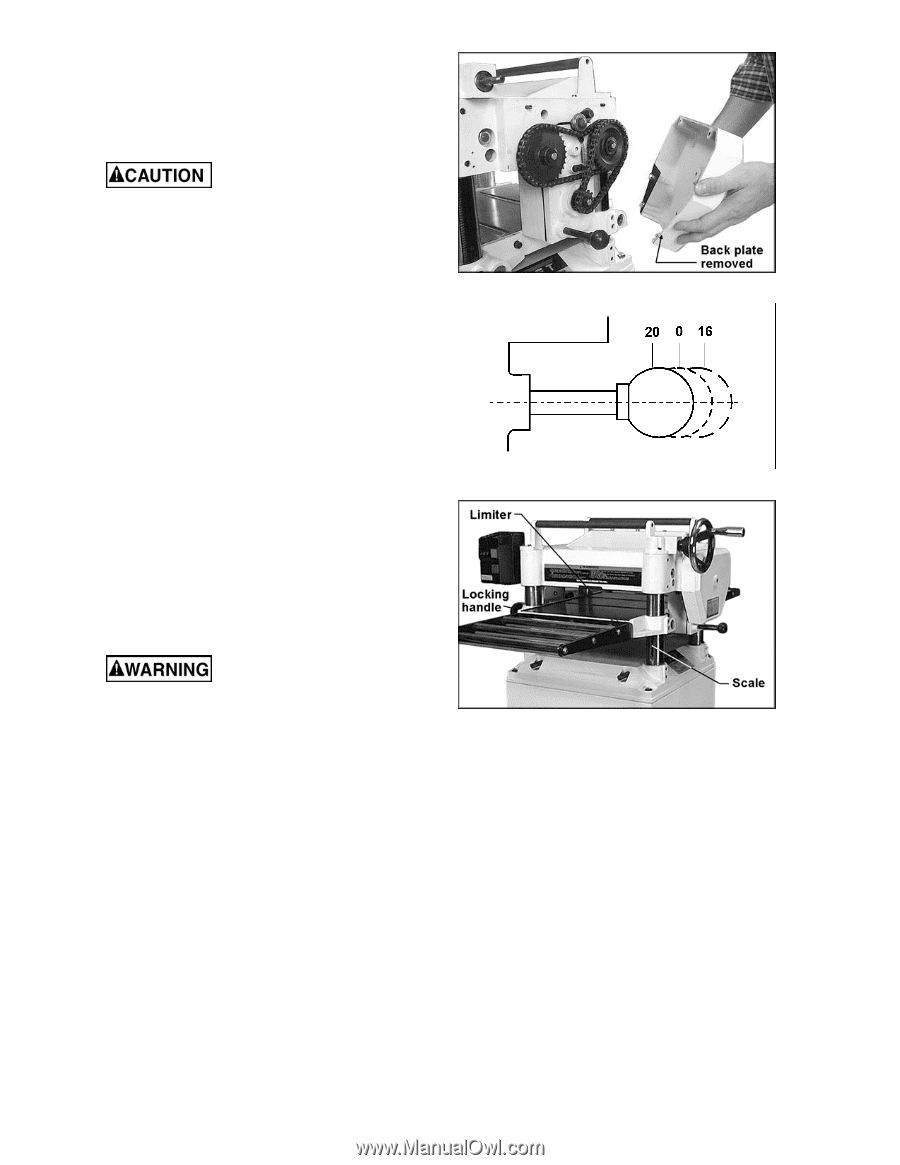

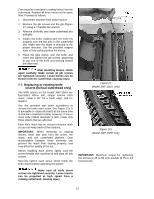

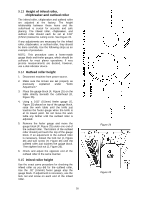

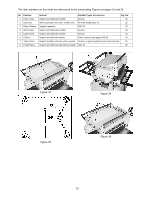

The gear box has two feed speeds. These are set by pulling out or pushing in the shift lever (Figure 30). Always change feed speed while the machine is running. A label showing the lever positions is affixed just above the lever. It is also shown in Figure 30. Do not attempt to change feed speed while stock is passing through the machine. Damage to the gearbox may result. 9.19 Stock return rollers The two rollers on top the machine serve as a convenient rest for stock. They save time and motion for the operator as the stock is returned to the infeed side. 9.20 Depth of cut The cutting depth scale (Figure 31) is a combination inch/metric scale, with a cutting range from 0 to 6" (152.4mm). The distance of upward or downward movement is controlled by the handwheel. Before moving the table up or down, loosen the locking handles (Figure 31). After obtaining proper table position, tighten the locking handles. Maximum depth of cut is 3/16". A limiter on the front of the head casting limits the depth of cut on full width planing under 1/8". 10.0 Maintenance Before doing maintenance on the machine, disconnect it from the electrical supply by pulling out the plug or switching off the main switch! Failure to comply may cause serious injury. Periodic inspections are required to ensure that the machine is in proper adjustment, that all screws are tight, that belts are in good condition and properly tensioned, that dust has not accumulated in the electrical enclosures, and that there are no worn or loose electrical connections. Buildup of sawdust and other debris can cause your machine to plane inaccurately. Periodic cleaning is not only recommended but mandatory for accurate operation. Close-fitting parts, such as the cutterhead slots and gibs, should be cleaned with a cloth or brush and non-flammable solvent, and freed from clinging foreign matter. 18 Figure 29 Figure 30 Figure 31